Zhejiang, a chemical company (Material: drying of sodium nitrite)

Application client:Product selection:

Detailed description

Products: Disc continuous dryer is a highly efficient conduction of continuous drying equipment. Its unique structure and operating principle determines that it has high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient control, good operating environment and other characteristics, widely used in chemical, pharmaceutical, pesticide, food, feed, farming product processing and other industries drying operation. Well received in various industries practice. Now manufacturing pressure, sealed, vacuum three types, 1200,1500,2200,3000 four kinds, A (carbon steel), B (contact material part of the uniform stainless steel), C (on the basis of B to increase the steam pipe Road, spindle and bracket stainless steel, lined with stainless steel barrel and cap top). Three materials, dry area 4 ~ 180m 2, a total of hundreds of models of products, and can provide a matching types of auxiliary equipment, users can meet the needs of a variety of materials to dry.  How it works: wet material continuously fed from the feeder on the upper portion of the first layer of drying plate dryer with rake leaf rake arm rotary movement of the digging arm rotary movement so continuously rake leaves turn copied material. Index material along the spiral flow through the disk surface drying, the material was dried in a small disk is transferred to the outer edge, and falls below the outer edge of the large drying plate at the outer edge, on a big plate material moved inward and drop from the middle spout off as one small drying pan. Size drying plates are arranged alternately, the material can be continuous through the whole dryer. Heating medium through the hollow of the dry plate, heating medium in the form of saturated steam, hot water or thermal oil heating medium enters from one end of the dry plate exported from the other end. Dried materials fell on the bottom of the housing from the last layer of drying plate, the last being transferred to rake leaves out of the discharge port. The moisture escaping from the material discharged from the humidity on the top cover of the mouth, a vacuum-type plate dryer moisture is discharged by the vacuum pump on the top cover of the mouth. Discharged from the bottom of the dry materials can be packed directly. By finned heater with addition, solvent recovery condensers, baghouse, dry material backmixing agencies, induced draft fan and other auxiliary equipment, can increase its drying capacity, dried paste and heat sensitive materials can be easily recycled The solvent and capable of heat decomposition and reaction.

How it works: wet material continuously fed from the feeder on the upper portion of the first layer of drying plate dryer with rake leaf rake arm rotary movement of the digging arm rotary movement so continuously rake leaves turn copied material. Index material along the spiral flow through the disk surface drying, the material was dried in a small disk is transferred to the outer edge, and falls below the outer edge of the large drying plate at the outer edge, on a big plate material moved inward and drop from the middle spout off as one small drying pan. Size drying plates are arranged alternately, the material can be continuous through the whole dryer. Heating medium through the hollow of the dry plate, heating medium in the form of saturated steam, hot water or thermal oil heating medium enters from one end of the dry plate exported from the other end. Dried materials fell on the bottom of the housing from the last layer of drying plate, the last being transferred to rake leaves out of the discharge port. The moisture escaping from the material discharged from the humidity on the top cover of the mouth, a vacuum-type plate dryer moisture is discharged by the vacuum pump on the top cover of the mouth. Discharged from the bottom of the dry materials can be packed directly. By finned heater with addition, solvent recovery condensers, baghouse, dry material backmixing agencies, induced draft fan and other auxiliary equipment, can increase its drying capacity, dried paste and heat sensitive materials can be easily recycled The solvent and capable of heat decomposition and reaction.

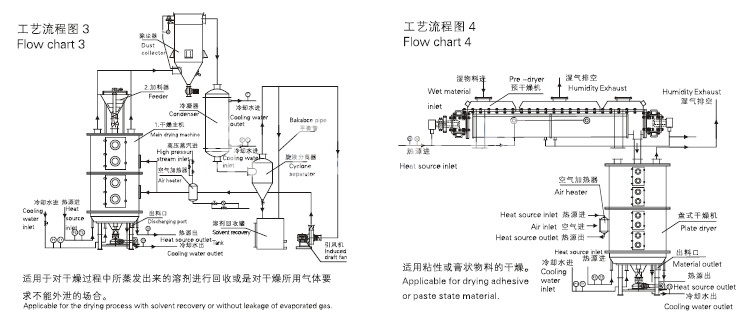

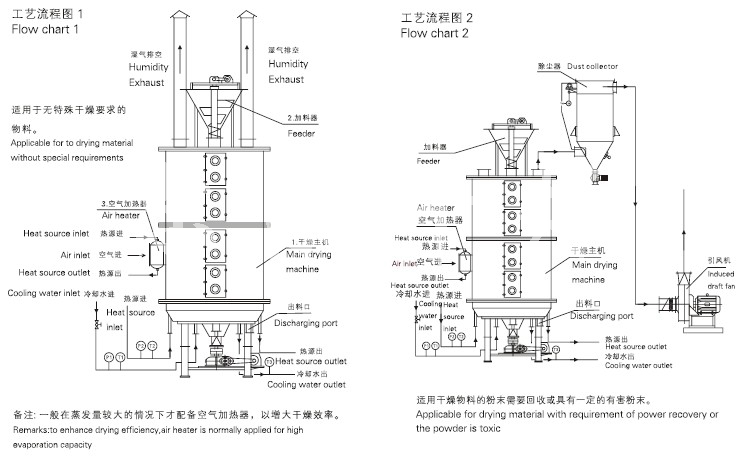

Features:(a) regulation of easy applicability ◎ by adjusting the thickness of material, spindle speed, number of rake arm, rake leaves type and size allows the drying process to achieve the best results. ◎ Each layer of drying plate can be led solely by the hot medium or cold medium, the material for heating or cooling, the material temperature control is accurate and easy. The residence time ◎ materials can be accurately adjusted. ◎ single flow of material without back-mixing, even drying and stable quality, no re-mixing. (B) simple, easy ◎ dryer drive, the parking operation is very simple. ◎ stop feeding, the transfer material dirt rake leaves can quickly emptying the dryer by. ◎ through a special endoscope large viewing window, it can within the device very carefully cleaning and observation. (C) low energy consumption ◎ Thin layer of materials, low spindle speed, material delivery system needs small power, less power consumption. ◎ by conducting heat drying, high thermal efficiency, low energy consumption. (Iv) operating environment, recyclable solvents, dust emissions to meet the requirements ◎ atmospheric type: Due to the low air velocity within the apparatus, and the humidity inside the equipment distribution compete with low dust is difficult to float to the top of the device, so the top of the moist discharge port exhaust emissions is almost no dust. ◎ hermetic: with solvent recovery device, can be easily recycled wet gas contained in the organic solvent. Solvent recovery is simple, high recovery rate for flammable, explosive, toxic and easy oxidation of materials that can be used wet nitrogen as the carrier gas in closed loop to make it safe to operate. Especially suitable for flammable, explosive, toxic materials drying. ◎ vacuum-type: disc dryer is operating under vacuum state, especially suitable for drying heat sensitive materials. Convenience (v) installation, small footprint ◎ drier overall factory, the overall transport, simply hoisting, positioning is very easy to install. ◎ Because drying plates being arranged by layers and installed vertically, even if a large drying area, the area is also very small. Technical characteristics:(a) drying trays ◎ design pressure: generally 0.4MPa, up to 1.6MPa. ◎ Maximum operating pressure: Usually ≤0.4MPa, up to 1.6MPa. ◎ heating medium: steam, hot water, thermal oil, drying plate temperature of 100 ℃, the use of hot water heating, 100 ℃ ~ 150 ℃ when ≤0.4MPa with saturated steam or superheated steam heating, 150 ℃ ~ 320 ℃ when conducting oil heating,> 320 ℃ can be used when electricity, oil, molten salt, etc. heated. (Ii) the material transport system ◎ spindle speed: 1-10 rpm, electromagnetic or frequency stepless speed. ◎ rake arm: 2 to 8 is fixed on the spindle rake arm on each drying trays. ◎ rake leaves: splice rake arm can float to remain in contact with the surface of the plate, take many forms. ◎ Roller: Easy caking and needs pulverized material, in place by placing roller can be enhanced heat transfer and drying process. (C) housing has pressure, sealed, vacuum three types ◎ atmospheric type: cylindrical or octagonal prism, there is a whole and split two structures. Heating medium can import and export the main channel in the housing and to be in housing. ◎ hermetic: a cylindrical casing, 5Kpa to withstand the internal pressure, the heating medium may be the main conduit and export in the housing, may be external to the housing. ◎ vacuum type: cylindrical housing design pressure 0.1Mpa, import and export the main channel of the heating medium within the housing. (Iv) air heater usually in the case of using a large amount of evaporation to increase drying efficiency. Adaptation materials:drying pyrolysis reaction was cooled combustion sublimation ◎ ◎ organic chemicals inorganic chemicals ◎ medicine, food ◎ feed, fertilizer

Technical Parameters:

| specification | OD mm | Height mm | Drying area m2 | Power Kw |

| 1200/4 | F1850 | 2718 | 3.3 | 1 |

| 1200/6 | 3138 | 4.9 | ||

| 1200/8 | 3558 | 6.6 | 1.5 | |

| 1200/10 | 3978 | 8.2 | ||

| 1200/12 | 4398 | 9.9 | 2.2 | |

| 1500/6 | F2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | F2900 | 3319 | 18.5 | |

| 2200/8 | 3739 | 24.6 | ||

| 2200/10 | 4159 | 30.8 | 4.0 | |

| 2200/12 | 4579 | 36.9 | ||

| 2200/14 | 4999 | 43.1 | 5.5 | |

| 2200/16 | 5419 | 19.3 | ||

| 2200/18 | 5839 | 55.4 | 7.5 | |

| 2200/20 | 6259 | 61.6 | ||

| 2200/22 | 6679 | 67.7 | 11 | |

| 2200/24 | 7099 | 73.9 | ||

| 2200/26 | 7519 | 80.0 |

| specification | OD mm | Height mm | Drying area m2 | Power Kw |

| 2500/6 | F3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | F3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 |